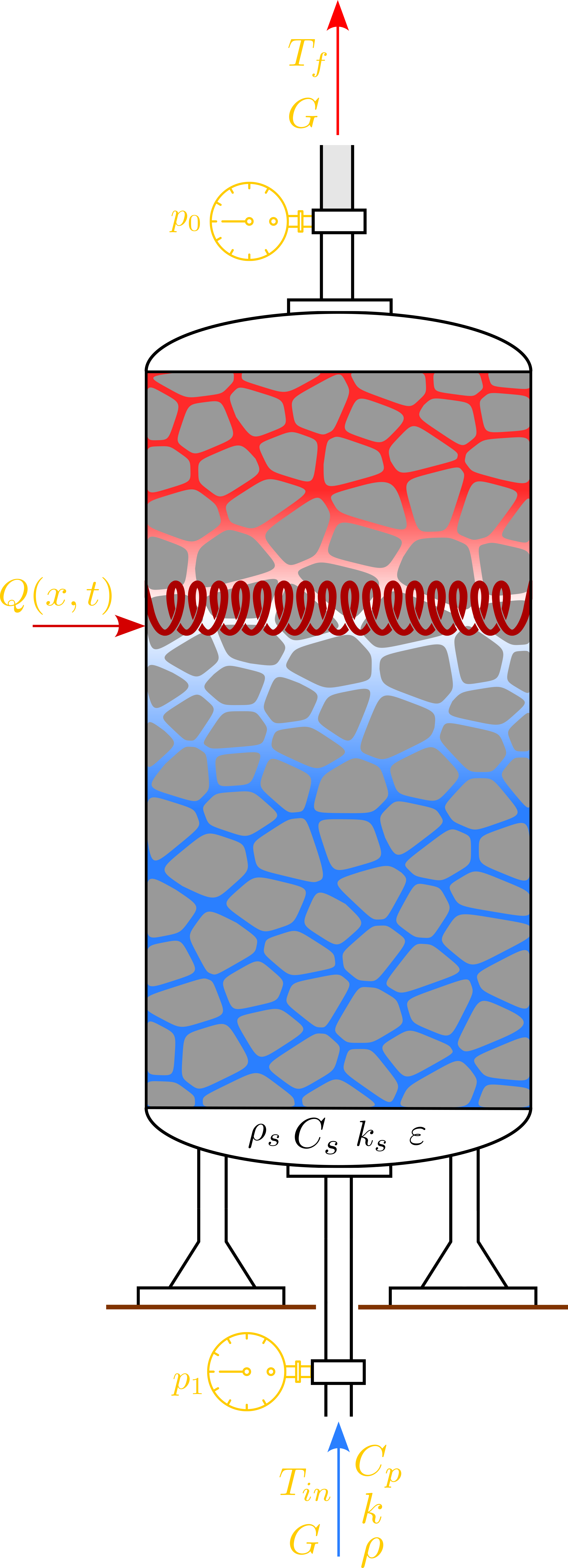

Localized heat source

We place the heating element inside the packed bed, around three quarters of its length, to guarantee a homogeneous temperature profile and fully leverage the applied thermal power.

A packed-bed tank architecture with a localized heat source that maximizes heat transfer and accelerates the decarbonization of high-temperature industrial processes.

A localized internal solution that redefines fixed-bed tanks for sensible thermal storage in high-temperature industrial applications.

We place the heating element inside the packed bed, around three quarters of its length, to guarantee a homogeneous temperature profile and fully leverage the applied thermal power.

The internal configuration maximizes exchange between the solid medium and the gas flow, increasing system efficiency and reducing exergy losses at the outlet.

IH-TESLA integrates into existing processes with minimal additional infrastructure, adapting to different gas mass flows, packing materials and thermal requirements.

Renewable or surplus energy feeds the internal heater, avoiding external conduction losses.

The heat-transfer fluid crosses the porous bed, storing sensible heat uniformly thanks to the controlled gradient.

Heat is released on industrial demand, with predictable outlet temperatures and high energy density.

IH-TESLA is backed by peer-reviewed research authored by Ramón Fernández Feria (Full Professor, Department of Mechanical, Thermal and Fluids Engineering, University of Málaga) and Antonio Martín Alcántara (Assistant Professor, Department of Mechanics, University of Córdoba).

Martín-Alcántara, A. & Fernández-Feria, R. (2025). Localized Internal Heating for Packed-Bed Thermal Storage. Applied Thermal Engineering, 250, 124004.

Access the publicationMartín-Alcántara, A. & Fernández-Feria, R. (2024). Asymptotic analytical solution for the temperature evolution in internally-heated packed-bed tanks for high-temperature solid-air energy storage. Applied Energy, 370, 122025.

Access the publicationihTESlabs was born from the collaboration between specialists in heat transfer and energy storage with experience in industrial and academic projects.

Co-founder · Scientific Direction

Assistant Professor at the Department of Mechanics, University of Córdoba.

Co-founder · Applied Research

Full Professor at the Department of Mechanical, Thermal and Fluids Engineering, University of Málaga.

We drive the decarbonization of industrial heat through thermal storage solutions that combine scientific rigor, industrial integration and rapid deployment. Our roadmap includes pilot-scale prototypes, collaboration with TES manufacturers and the development of modular IH-TESLA systems.

Technical answers based on our recent IH-TESLA studies.

Thanks to their thermophysical properties, materials with high thermal diffusivity reach the target outlet temperature in less time. For the same thermal jump, they enable operation at higher power levels.

For example, an IH-TESLA tank filled with alumina and operating at 10 kW needs about five hours to achieve a 1000 K jump. With SiC particles and 100 kW, less than two hours are required (see Figs. 1 and 3 in Martín-Alcántara & Fernández-Feria, 2025b).

If the design power is fixed, a smaller temperature rise implies higher gas consumption (Eq. 11) and, consequently, a larger tank. Filling with higher-diffusivity particles mitigates this effect, albeit at a higher cost. The final choice depends on industrial needs.

Reducing heating time requires a more compact tank or particles with elevated thermal diffusivity. According to Eq. 5, decreasing the device size shortens the time needed to reach the target temperature while keeping the remaining parameters constant.

Placing the internal source outside 70‑80 % of the tank length results in suboptimal behavior. Outputs deviate from our studies and parameters (materials or operating conditions) would need adjustment to meet requirements. The patent defines a ±10 % margin to ensure performance.

It depends on plant needs (thermal jump, power and heating time). An optimal IH-TESLA tank can always be sized, but the decision to use one or several units is conditioned by economics, interconnection capacity and available space. A single unit distributing the energy is usually preferred.

An interruption in the supply forces the charging process to restart. The tank will once again take the heating time to reach the industrial requirements, making that variable critical during design and operational planning.